The world leader in bearings manufacturing LLC SKF and VibroBox have agreed on the partnership

VibroBox and SKF office in Minsk have a long history of cooperation in the field of vibration diagnostics of industrial equipment. Since the spring of 2018, VibroBox has also established strong connections with SKF Moscow office (LLC SKF, Moscow). During the period from 6th of April till 7th of June 2018, SKF team tested VibroBox system for automatic assessment of the technical condition of industrial equipment.

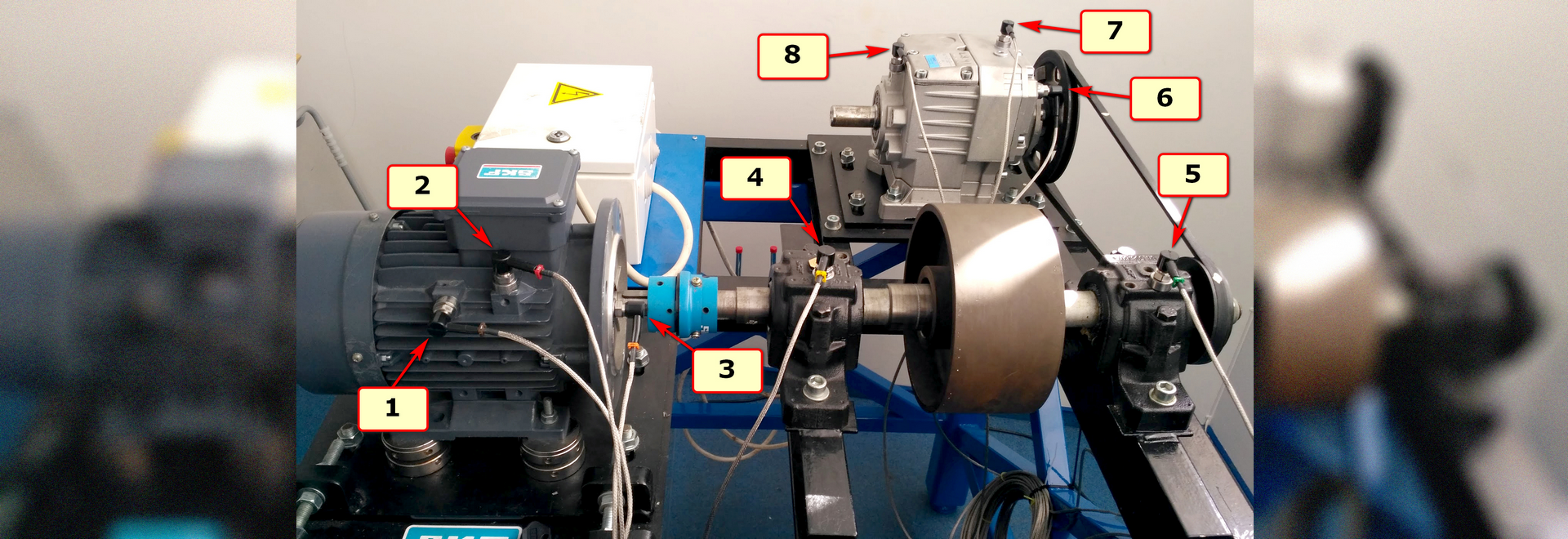

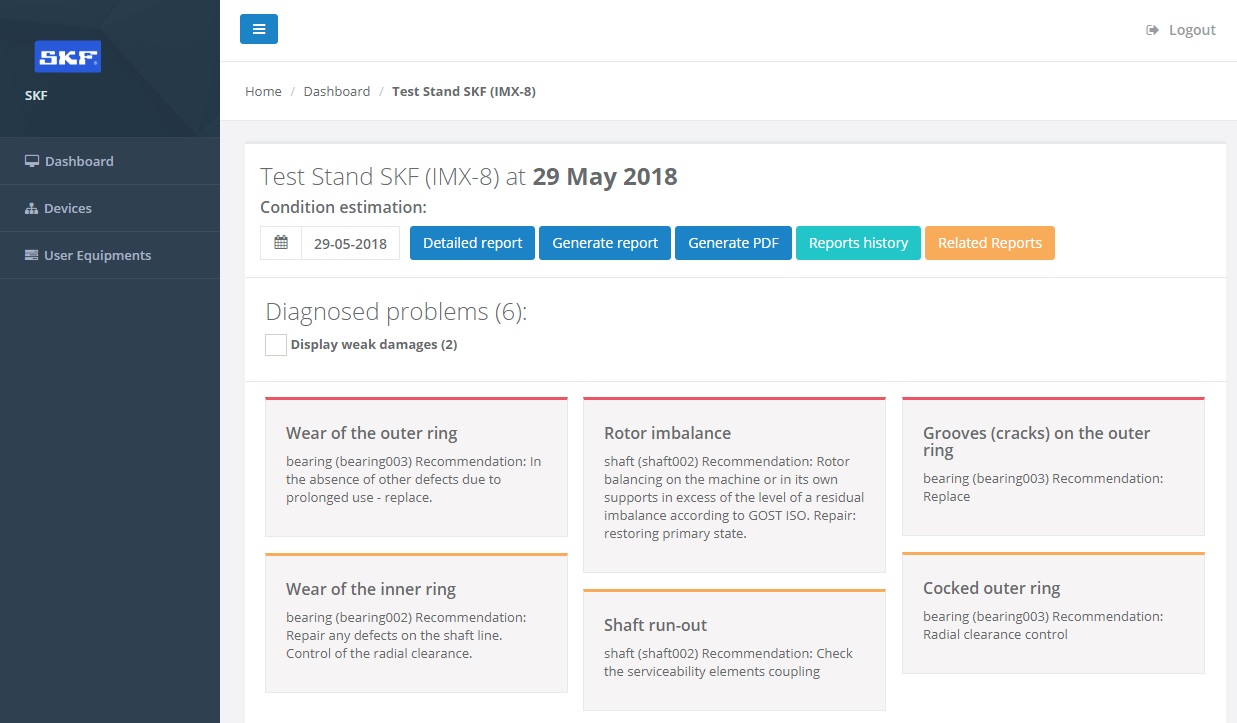

The primary goal of the experiment was the practical confirmation of the functionality, efficiency, and reliability of the VibroBox system. SKF provided diagnostic equipment and software for data collection during the tests. VibroBox Cloud Processing System analyzed vibration data, detected defects and issued recommendations on the technical condition of the equipment remotely from Minsk.

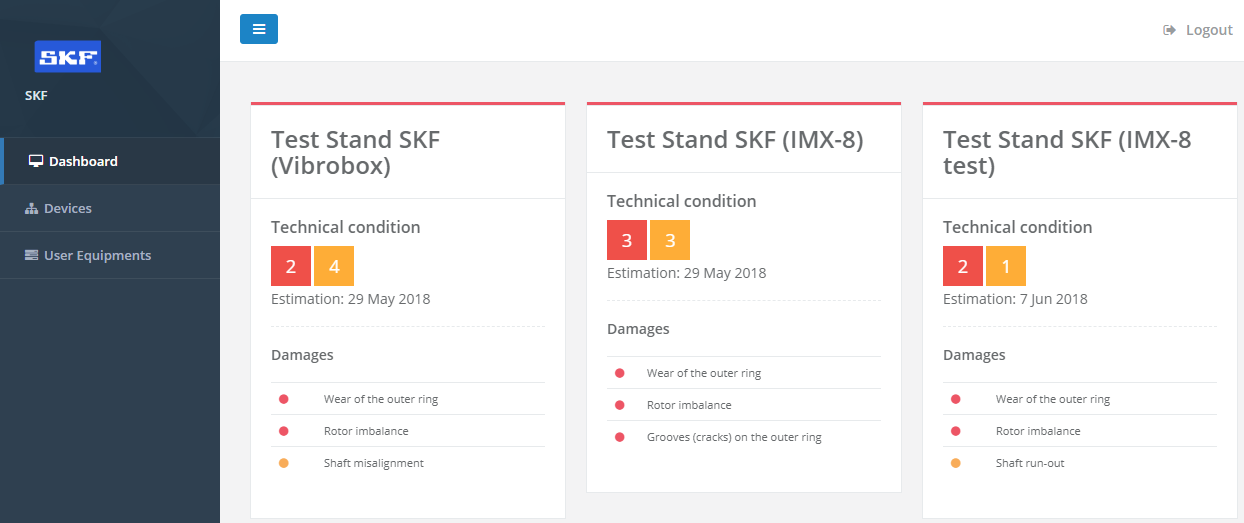

VibroBox system achieved a very high detection rate of defects. Almost 100% of probing cases were correctly recognized. The only case in question was an unexpected manual bearing replacement (however, now VibroBox correctly processes similar cases). Most importantly, the VibroBox team was not present during the experiment in Moscow, all tests were performed by SKF team only. This emphasizes the objectivity of achieved results and confirms the high efficiency of the VibroBox solution.

Having evaluated the test results, SKF named the VibroBox solution as promising. The companies outlined further actions to expand cooperation, including the implementation of joint commercial projects in Russia.

The VibroBox team thanks colleagues from SKF for the trust and professional support of the project!

Siarhei Vasiukevich with SKF colleague.

SKF test equipment.

Results of experiment.

Defects which were found during one of the experiments.